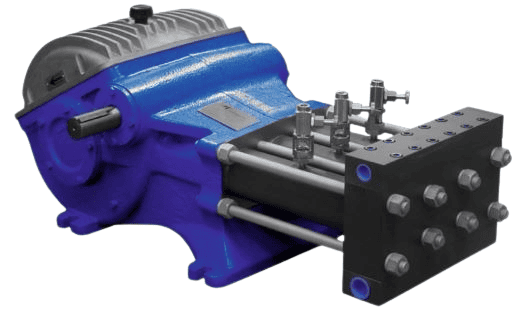

DP Series

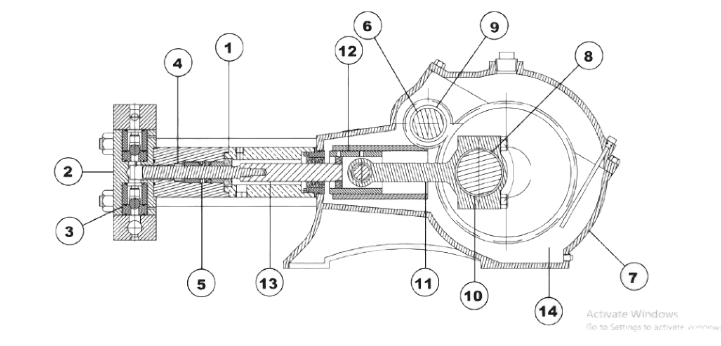

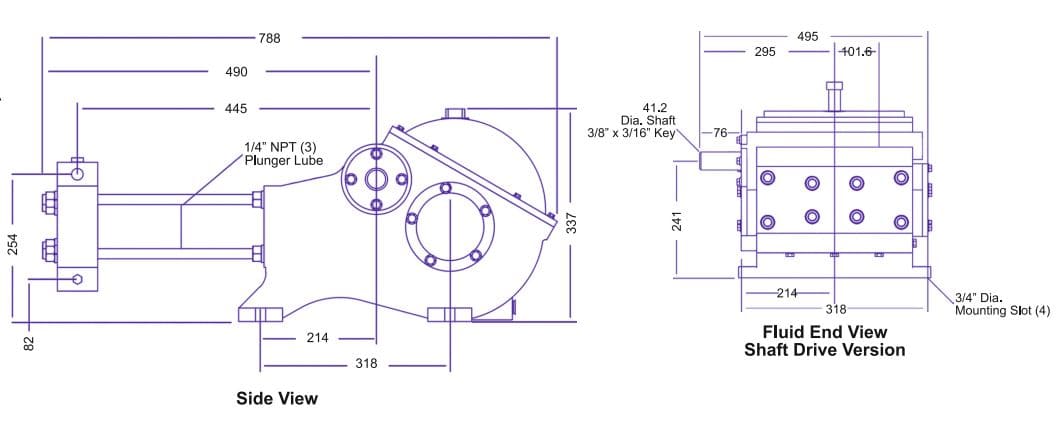

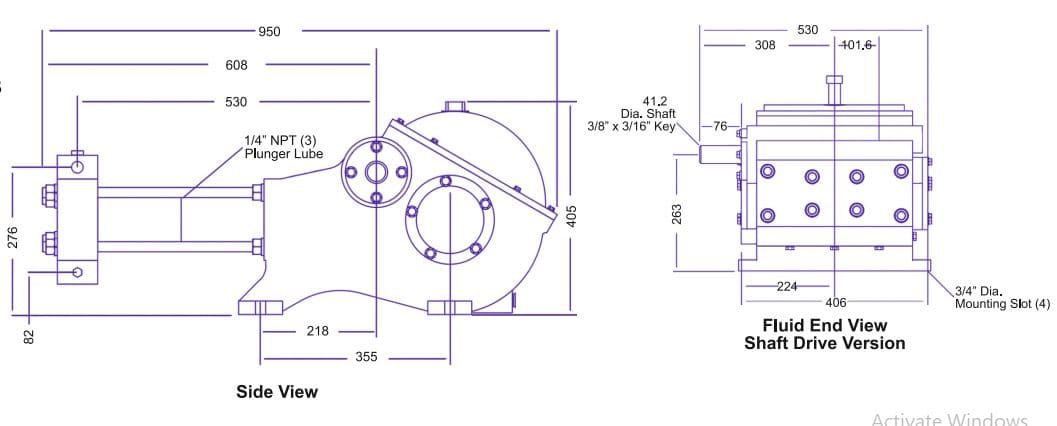

WSSP largest high volume/pressure series offers interchangeable plungers, seals, and fluid ends to provide various flow/pressure ratings. Available in Hydraulic drive, FLP-non-FLP motors or Engine drive configurations.

DP Series Features:

- Flows to 430 LPM

- Pressure ratings up to 700 BAR

- Internal gear reductions for low speed

- Super hard, non-scoring plungers

- Fluid end options - S.G. lron, AISI 410 or Stainless steel.

- Ball valve option for mud pumping available.

- Available with FLP - non FLP Motors/Engines/Hydraulic Motors.